Simultaneous material transfer between presses enables the cost-effective production and personnel reduction Servo 2~4 axis motion control realizes outstanding circle interpolation control Mold change time shortened and operation status can be easily indentified through model management system by items Tact time shortened and reversal/centering processes can be easily added by applying idle Automatic adsorption • desorption arms can be easily changed

| Model | SH-2000~SH-5000(Idle is optional) |

| Feeding Stroke | 2,000mm~6,000mm(Idle: 1,000mm~3,000mm) |

| Up/Down Stroke | Max. 80mm~150mm |

| Material Weight | Max. 3.5kg~15.0kg |

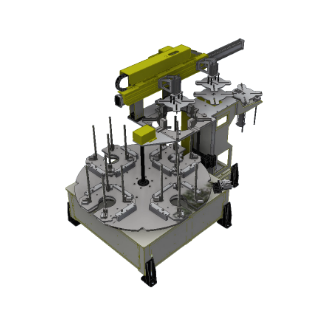

Possible to stack a large quantity of sheets

Automatic stage changes

Suitable for mass production of multi items

| Stacking Stage | 4~6 |

|---|---|

| Stacking Weight | 500kg/1 Stage(Max. 2,000kg) |

| Lift | Hyd’ or Geared Motor |

| Lift Weight | Max. Motor 500kg |

| Max. Hyd’ 2,000kg |

Suitable for mid-sized materials

Automatic stage change

Suitable for mass production of limited items

| Stacking Stage | Max. 10 |

|---|---|

| Stacking Weight | 500kg/1 Stage(Max. 2,000kg) |

| Lift | Hyd’ or Geared Motor |

| Lift Weight | Max. Motor 500kg |

| Max. Hyd’ 2,000kg |

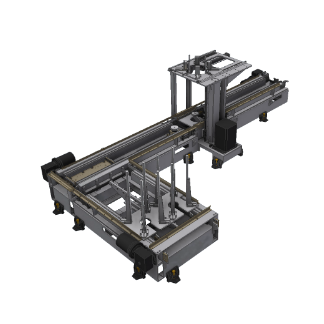

Suitable for large-sized materials and heavy weights

Automatic stage change

Suitable for large-sized BLK' and sheet materials

| Stacking Stage | 2 |

|---|---|

| Stacking Weight | 2,500kg/1 Stage(Max. 5,000kg) |

| Lift | Hyd’ |

| Lift Weight | Max. Motor 500kg |

| Max. Hyd’ 10,000kg |