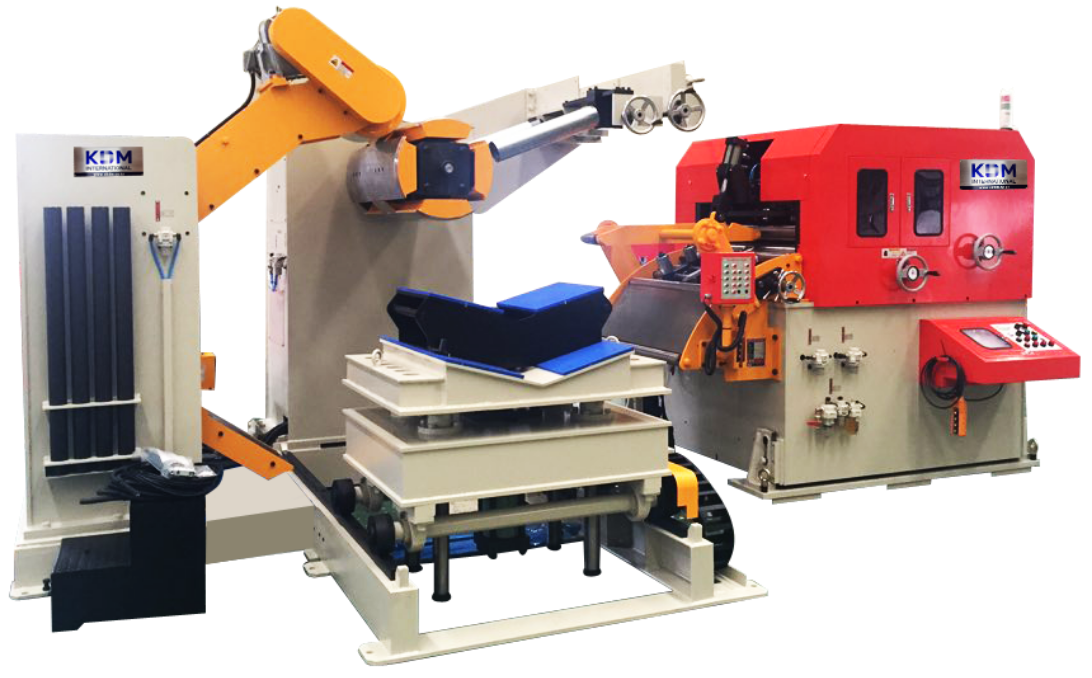

A roll structure suitable for medium/thick plates Pad bands and coil lift applied to facilitate the insertion of coils in the initial stage Mechanical-brakes for absorbing inertia in the uncoiler and caliper brakes applied Possible to prevent coil from twisting by applying uncoiler and opener inverter controls

MT LINE SPECIFICATION

| MT-MODEL | ||||||

| Unit | 300MT-500MT | 600MT-800MT | 900MT-1200MT | 1300MT-1500MT | 1600MT-1800MT | |

| THICKNESS | mm | 0.8~6.0 | ||||

| COIL WIDTH | mm | 100~500 | 100~800 | 100~1,200 | 100~1,500 | 100~1,800 |

| COIL OUT DIA | mm | 1,500(2,000) | ||||

| COIL WEIGHT | Kg | 5,000~20,000 | ||||

| FEEDING LENGTH | mm | Max Input Value 9999.99 | ||||

| LINE SPEED | m/min | 22 | ||||

MT Levelling correction capability Based on tensile strength of : 45kgf/㎜ 2

| 300MT | 400MT | 500MT | 600MT | 700MT | 800MT | 900MT | 1000MT | 1200MT | 1400MT | 1600MT | 1800MT | ||

| LEVELLER ROLL LENGTH(mm) |

330 | 430 | 530 | 630 | 730 | 830 | 930 | 1,030 | 1,230 | 1,430 | 1,630 | 1,830 | |

| THICKNESS (mm) |

0.8~1.6 | 250 | 350 | 450 | 550 | 650 | 750 | 850 | 950 | 1,150 | 1,350 | 1,550 | 1,750 |

| 1.8 | 860 | 860 | 860 | 860 | 860 | ||||||||

| 2.0 | 740 | 730 | 700 | 700 | 700 | 700 | 700 | ||||||

| 2.3 | 700 | 670 | 640 | 640 | 640 | 640 | 640 | ||||||

| 2.8 | 630 | 580 | 530 | 530 | 530 | 530 | 530 | ||||||

| 3.2 | 570 | 510 | 450 | 370 | 370 | 370 | 370 | 370 | |||||

| 4.0 | 430 | 400 | 380 | 350 | 350 | 250 | 250 | 250 | 250 | ||||

| 4.5 | 310 | 290 | 290 | 250 | 250 | 230 | 200 | 200 | 200 | ||||

| 6.0 | 200 | 200 | 190 | 190 | 170 | 170 | 150 | 130 | |||||

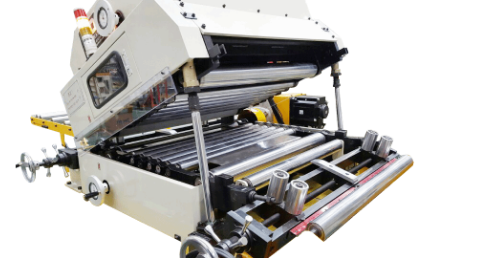

Easy to clean rolls by opening work rolls

For MG/SL models only

Leveller feeders move from side to side to perform multiple processes of circular blanks

Used to cut the front or end part of coils when recoiling

Hydraulically driven

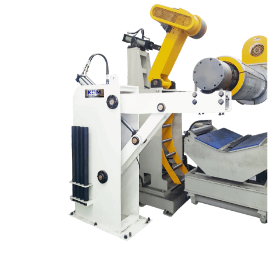

Possible to prevent uncoiler from sagging when using materials of

more than 1,200㎜x10Ton

Semi automatic types: Oil injection according to timer setting

Automatic types: Oil injection according to timer setting, oil reuse through recycling system

The type is composed of two uncoilers and can reduce working time of coil replacement in advance by installing coil in another uncoiler waiting for next operation

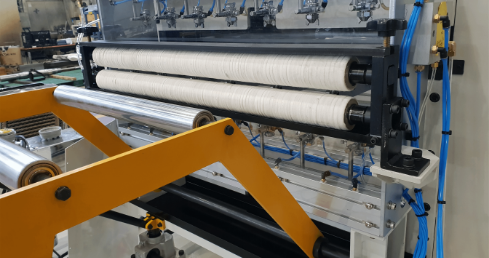

Operated by servo motors

For same operations, automatic setting is possible after memorizing the amount of levelling adjustment for each coil