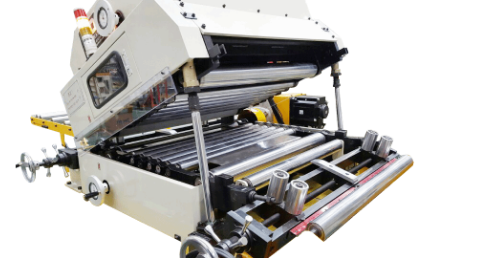

Precise levelling of fine blanks and sheet materials High quality products and high accuracy can be realized by applying work roll cassette type Optimal roll condition can be maintained by opening and cleaning work rolls Through memory function, levelling can be easily performed after changing model types High productivity by applying coil auto loading system

FINE BLANKING / SHEET-LEVELLER SPECIFICATION

| FINE BLANKING / SHEET-LEVELLER-MODEL | |||||

| Unit | FBL-150 | FBL-320 | FBL-600 | FBL-1000 | |

| THICKNESS | mm | 0.1~1.5 | 1.0~3.2 | 3.2~6.0 | 5.0~10.0 |

| COIL WIDTH | mm | 100~400 | 100~600 | 200~800 | 200~1,200 |

| LINE SPEED | mm | 10~16 | |||

| WORK ROLL | ∅ | 35~45 | 45~65 | 55~75 | 75~90 |

| Pcs | 15~21 | ||||

Easy to clean rolls by opening work rolls

For MG/SL models only

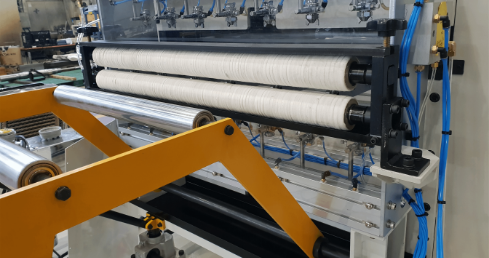

Leveller feeders move from side to side to perform multiple processes of circular blanks

Used to cut the front or end part of coils when recoiling

Hydraulically driven

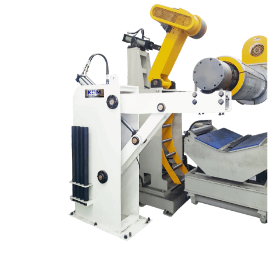

Possible to prevent uncoiler from sagging when using materials of

more than 1,200㎜x10Ton

Semi automatic types: Oil injection according to timer setting

Automatic types: Oil injection according to timer setting, oil reuse through recycling system

The type is composed of two uncoilers and can reduce working time of coil replacement in advance by installing coil in another uncoiler waiting for next operation

Operated by servo motors

For same operations, automatic setting is possible after memorizing the amount of levelling adjustment for each coil